Calibration Plates

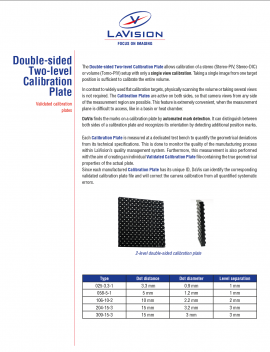

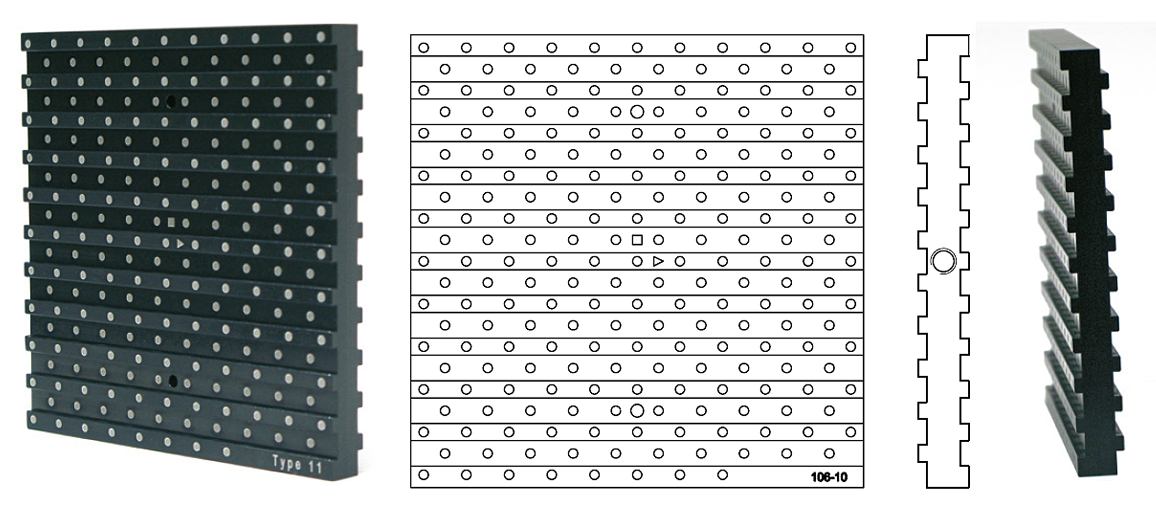

3D Calibration Plate

The basis for accurate multi-dimensional strain experiments is a precise calibration of the two (or more) cameras. LaVision employs a fully empirical calibration method, which does not involve measuring physical angles or distances. It has been proven to be highly accurate and reliable.

For the calibration of stereoscopic camera systems LaVision provides 3D Calibration Plates with defined separation of the calibration planes and mark spacing.

- High precision dot pattern

- Two-level double-sided pattern suitable for simultaneous calibration from opposite sides

- Fducials for automatic mark search identifying front and back side automatically

- Screw thread on border for easy mounting

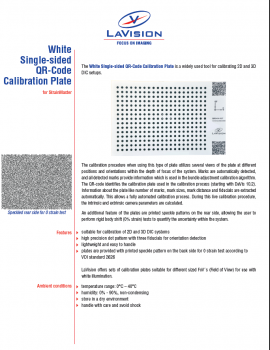

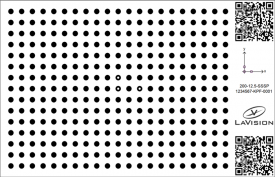

Single-sided QR-code Calibration Plates

White or fluorescent Single-sided QR-Code Calibration Plates are a widely used tool for calibrating 2D and 3D DIC setups. The QR-code contains all the necessary information required for calibration. The calibration procedure when using this type of plate utilizes several views of the plate at different positions and orientations within the depth of focus of the system. Marks are automatically detected, and all detected marks provide information which is used in the bundle adjustment calibration algorithm. During this live calibration procedure, the intrinsic and extrinsic camera parameters are calculated. LaVision offers sets of calibration plates suitable for different sized FoV's (Field of View) for use with white or blue illumination.

An additional feature of the plates are printed speckle patterns on the rear side, allowing the user to perform a zero-strain test, according to the VDI2626 standard.

- Suitable for calibration of 2D and 3D DIC systems

- High precision dot pattern with three fiducials for orientation detection

- Lightweight and easy to handle

- Plates are provided with printed speckle pattern on the back side for 0 strain test according to VDI standard 2626

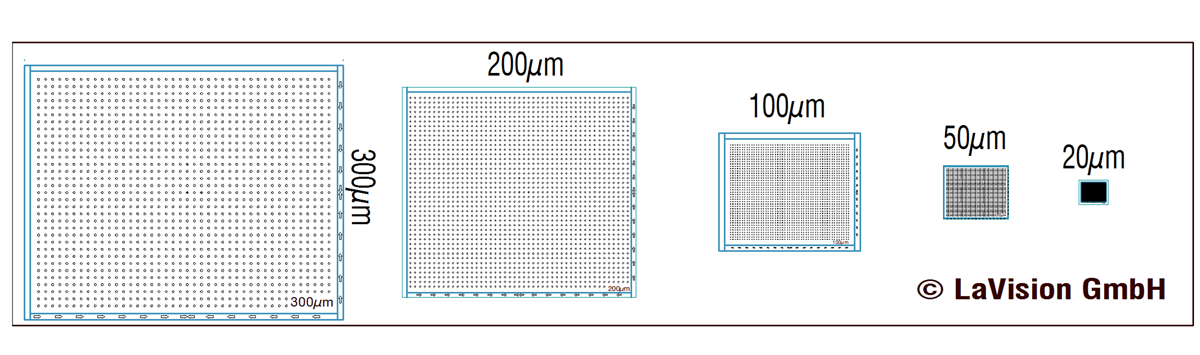

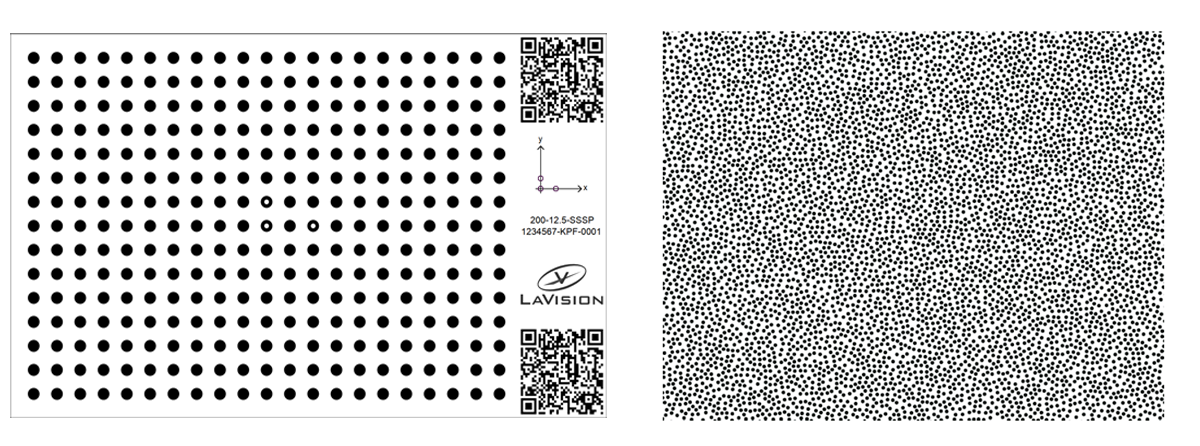

Micro Calibration Plates

These Micro Calibration Plates can be used for calibration purposes for µDIC StrainMaster systems with small scale fields of views (FoV).

There are various types of plates available with several targets of different dot diameters and distances.

Material:

- glass substrate with protective coating

or - orange glass substrate- orange fluorescence when excited with green light