Digital Image Correlation (DIC)

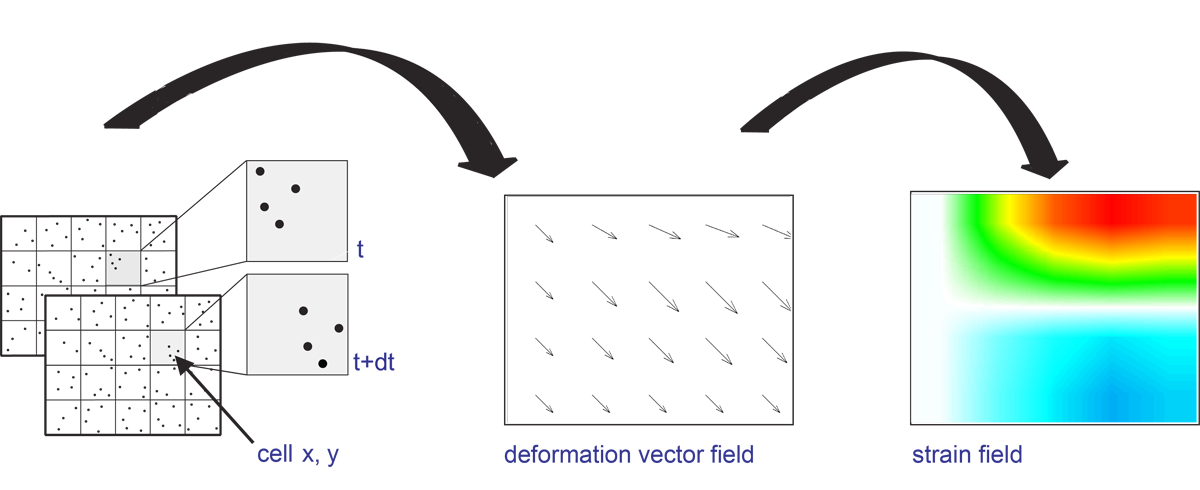

Digital Image Correlation (DIC) effectively tracks the movement of the naturally occurring, or applied surface pattern during the test or experiment. This is done by analyzing the displacement of the patterns within discretized subsets or facet elements of the whole image. The maximum correlation in each window corresponds to the displacement, and this gives the vector length and direction for each window. Advanced algorithms use multi-pass processing, window deformation, and the possibility of non-square subsets to maximize the sub-pixel accuracy.

Digital Volume Correlation (DVC)

Digital Volume Correlation (DVC) is a novel technique for full 3D strain and deformation measurements. The technique imports volume images of the component in reference and deformed states and is able to calculate the full 3D displacement and strain map. Images are typically acquired from X-ray Computed Tomography (X-ray CT) systems, but can equally be obtained by Magnetic Resonance Imaging (MRI) systems for biological subjects, or via optical tomography for transparent media; for which LaVision offer our tomographic reconstruction algorithms as an add-on. DVC is a powerful non-intrusive technique for the identification of sub-surface material deformation and is capable of identifying defects, discontinuities or other material characteristics.

In order for Digital Volume Correlation to be successful the volume images must contain a random pattern. That random pattern is seen as changes in local contrast. In the case of X-ray CT scans the pattern will be produced by changes in material density such as air voids in concrete, or particles of different material type within the main body matrix, such as Digital Volume Correlation (DVC) tin particles distributed in an aluminium powder. The volume image is sub-divided into interrogation volumes within which robust and highly accurate algorithms calculate the displacement of the pattern, which represent the material shift. Digital Volume Correlation is capable of yielding over one million displacement vectors per volume image pair.