Particle & Droplet Imaging

In-situ monitoring of particles improves product quality and can help to optimize the efficiency of particle based processes.

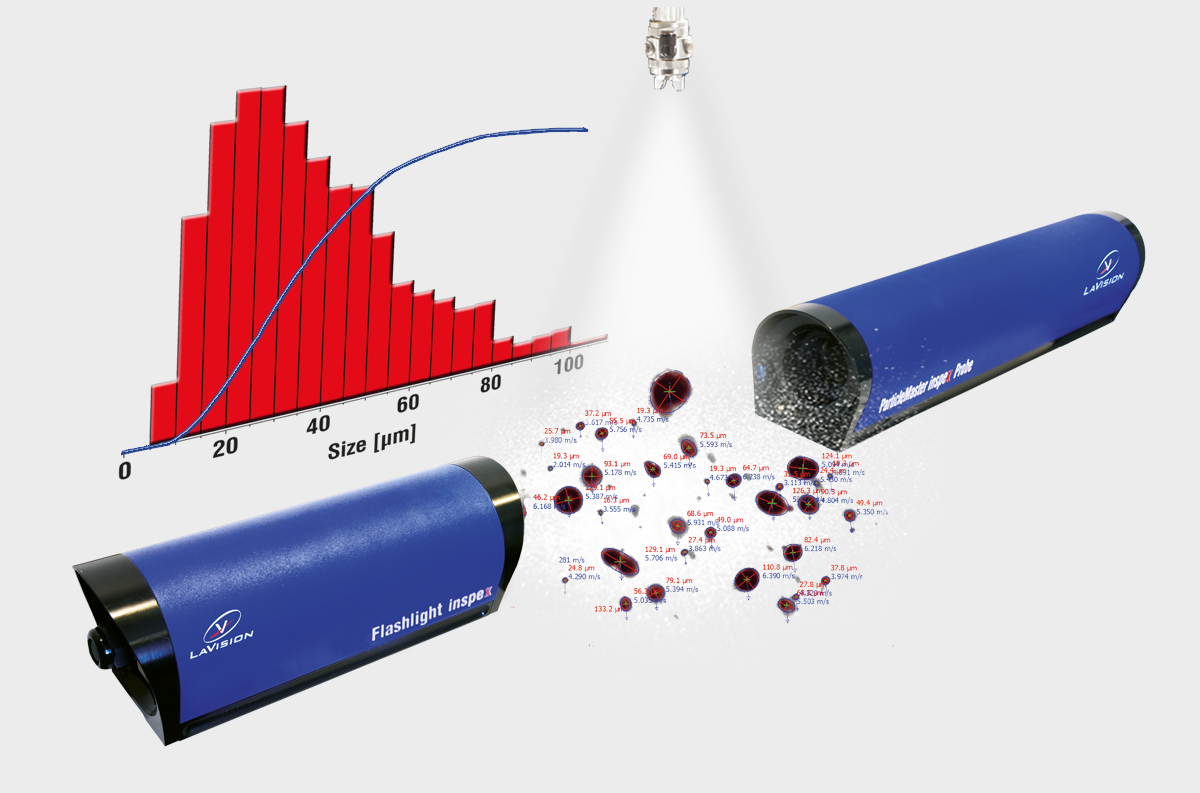

LaVision’s ParticleMaster inspex systems visualize and analyze particle size, shape and velocity applying high magnification shadow imaging. Particles can be solid particles, droplets or gas bubbles with physical dimensions ranging from 4 µm to several millimeters in size. Good statistical sampling for robust quality control measurements is achieved recording a large number of particles at high data rates.

For further information please refer also to our new site for industrial applications.

- Spray testing: water, fuel, paint, household

- On-line control of powder, solid particles: alloys, ceramics, grains

- Inspection of bubbles: heat exchanger, industrial processes

- Particle monitoring in spray dryers

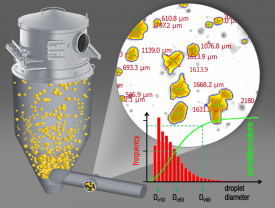

Particle and Droplet Monitoring in Sprays

Particle and droplet characteristics in spray processes and production of spray devices are fundamental for the quality of the end product.

Online particle monitoring in production processes

Food stuffs, chemicals, pharmaceuticals, cosmetics and building materials are often provided in the form of powders and granulates. The production of these is a central part of many processes. Online monitoring of the product and process is essential to reduce production costs and ensure quality.

ParticleMaster inspex probes and software are designed for 24/7 online monitoring of particle characteristics.

- instantaneous indication of process status

- Continuous monitoring of product quality

- Online control loop to optimize production parameters

- Immediate warning when production errors occur

ParticleMaster Imaging Systems

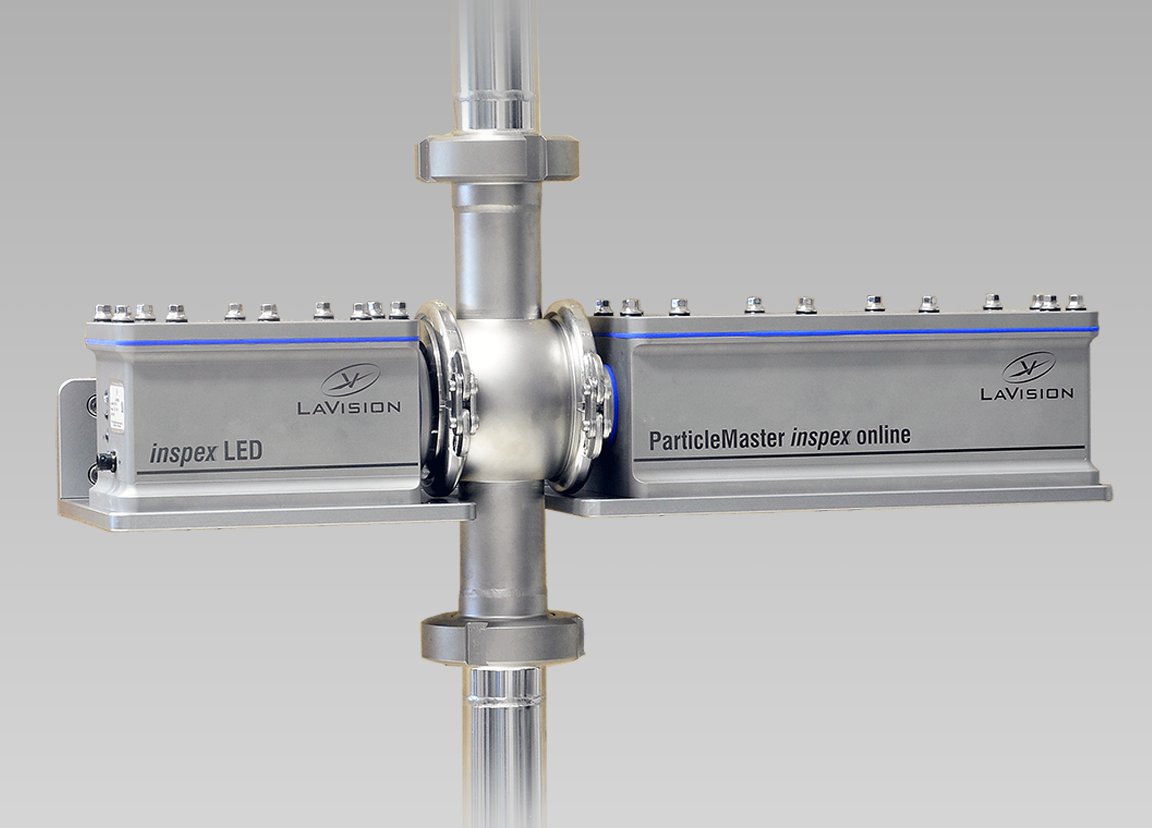

The ParticleMaster inspex systems are available in a variety of setup configurations, each optimized for a your application scenario. For manual sample testing a benchtop system offers the highest flexibility for laboratory use. The on-line probe configuration offers a higher process integration for continuous particle monitoring in e.g. a bypass flow cell.

|

|

| ParticleMaster inspex online probe installed at process sight glass |

ParticleMaster inspex in emitter-receiver configuration |

These compact and highly integrated imaging systems are especially designed for quality control applications in industrial environments. The instruments are factory calibrated, splash-proof and eye-safe with a well-defined mechanical interface for test bench integration.

- In-situ particle imaging: size,shape, velocity with statistics

- No sample preparation required for transparent probe volumes

- Compact self-contained probes and lights

- Fully factory calibrated for particle size and probe volume dimensions

- Automated particle image recording and analysis

In addition to other particle analysers, the imaging approach also reveals absolute particle number density, volume fraction and mass flux.

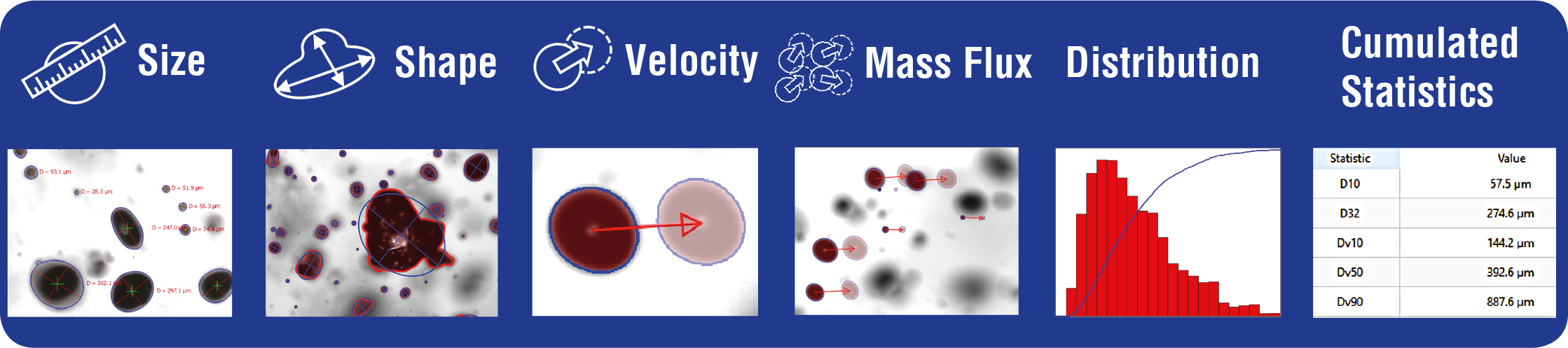

- Size and shape: diameter, perimeter, circularity …

- Velocity and mass flux

- Cumulated statistics D10, D32, percentiles Dv10, Dv50, Dv90

- Size histograms, scatterplots

ParticleMaster Software

The ParticleMaster inspex software package automatically identifies valid particles in the recorded images and calculates all relevant particle properties with outstanding processing speed including statistical information in real-time.

As the ParticleMaster inspex systems are based on imaging, the visual feedback of highly resolved particle images gives you the necessary confidence in the quality of the measurement.